What Attachments Do You Need on a Forklift for Your Business?

Forklift attachments are important when moving/ rotating material handling goods. The attachments are connected to the carriage that is connected to the mast which holds the load in place. There are various kinds of attachments to choose from. We will just focus on the 8 main ones to give you a better understanding of which forklift attachments are used in which circumstance. Each attachment has its own unique purpose so the forklift can be used in a variety of applications. There are forks, sideshifters, fork positioners, rotators, clamps, carton clamps, paper roll clamps and push pulls.

Forklift Attachments

Forks

Forks are the standard attachments you get when purchasing a forklift, the forks come in pairs. When using the forks with any applicable attachment, you must use at least 2 forks at a time. The load should not be balancing on 1 fork, that’s a hazard to everyone in the warehouse or building. The forks have various sizes, the standard size most forklifts come with are 1.5” x 4” x 42” called pallet forks. There are different fork types, pallet forks, and plywood forks. When using the pallet forks the load has to be placed on a pallet or some sort of spacer for the forks to go underneath to lift up the load. The Forks can also be attached to sideshifters, and fork positioners to make it easier to move the forks.

Sideshifter

Sideshifter attachments use forks to grab the load. The forklift operator can shift the forks left or right without having to readjust the forklift and the forks move in unison left or right. Using a sideshifter would be helpful when trying to pick up or put away a load in a warehouse and the forklift isn’t exactly in line with the load.

Fork Positioner

Fork Positioner attachments use forks to grab the load. If your warehouse has varying size loads the fork positioner can be adjusted easily. Since the forks move in and out simultaneously or independently, the forks can pick up loads small and large. These are commonly used when a company utilizes multiple different sized pallets.

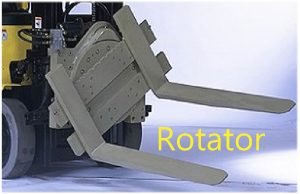

Rotators

Rotator attachments are used to rotate, dump, or pour loads. Forks and clamps can be rotators. They can rotate 360 degrees, but can be stopped mid-rotation depending on the task requirement. The clamps open then close to grip the load securely. Whereas the forks would slide under the load holding on to the load securely.

Clamps

Clamp attachments can be virtually any size and shape. The clamp is used to grab loads so when the load isn’t on a pallet or supported, the clamps could be used. It also depends on if the load can be grabbed from the sides, some loads can be moved by grabbing them. A good use for clamps would be for moving crates, boxes or blocks of foam.

Carton Clamps

Carton clamp attachments has the same purpose as regular clamps, but they are just bigger. They are used to move appliances like washers and refrigerators, or cased products like beverages, paper and tissue products. If the stacked loads are close together, there are carton clamps that are made with different side thicknesses to fit different warehouse needs. They also clamp the crates and boxes from the sides.

Paper Roll Clamps

Paper roll clamp attachments are used for large rolls like the paper rolls. There are different versions of this clamp, but they all are a half circle making it optimal to grab the cylinders easily. Some paper roll clamps have the rotator attachment so the load can be rotated as well. They clamp cylindrical shapes, making it easier to move drums or barrels.

Push pull attachments

Push pull attachments also known as slip sheeters are best used for cargo that doesn’t have clearance for traditional forks. Also, the push pull attachments can be used when moving goods from the floor to a pallet or from a pallet to the floor . To move the goods this attachment pulls the goods towards the forklift onto thin forks. When placing the goods in a different location the attachment then pushes the cargo off the thin forks to its new destination.

All the attachment types have various makes and models that cater to a wide range of tasks that can be performed. Each attachment type can be combined with another attachment type. For example, the rotator paper roll clamps are a rotator attachment and a paper roll clamp attachment, or the sideshifting positioners are the sideshifter and positioner attachments combined. When purchasing a forklift typically the attachment that comes with it is a sideshifter with pallet forks. It is good to note when purchasing an attachment the forklift dimensions will be affected, since the attachments aren’t the same size. In addition, any time an attachment is added to a unit it will affect the lifting capacity as the load center is affected by the thickness of the attachment. Make sure to ask your dealer how different attachments will affect your lifting capacities.

This article is to provide guidance to which attachments should be used at your company. There’s so much more information you will need to know when purchasing a forklift.

Stay tuned for our next article next month. If you are interested in purchasing a forklift contact us. Do you have a topic for an article? Comment down below.